From Waste To Wonderful

High-Performance Sustainability, Reimagined…

At the heart

of every product we make

is innovation with purpose.

Fleks isn’t just simply made from premium recycled materials — it’s footwear reimagined. Every material, every product, every step we take proves sustainability can be bold, beautiful, and built to perform.

Blumaka is the sustainable materials and technology partner that

FLEKS Footwear relies on for its foam. Built to FLEKS’ specifications, Blumaka

provides proprietary high-performance foam components made from recycled waste to enable stylish, comfortable, durable, and planet-friendly footwear.

Proprietary Formula

What is Blumaka Foam?

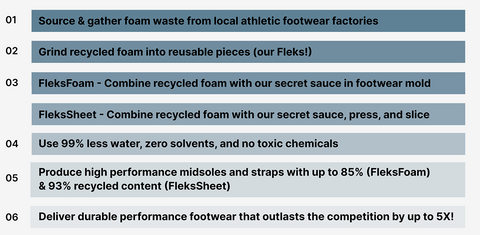

Sourced from premium foam remnants—ETPU from some of the highest-performance athletic shoes in the world—Blumaka Foam gives these high-quality, otherwise discarded scraps a second life.

Blended with our proprietary formula and molded to perfection, Blumaka Foam contains up to 85% recycled content by volume — offering a sleek, finished look using only 2 tablespoons of water to make, and zero compromise on performance.

In fact, the way we've repurposed the foam makes it even more durable than what it was originally crafted for. We gather, grind, and reform these materials into something new — extending their lifecycle and redefining their purpose.

FLEKSsheet

sustainability in full spectrum

What Is FLEKSsheet?

FLEKS created an innovative and exclusive

material fabrication process using Blumaka foam — the result is FLEKSsheet, a

proprietary FLEKS innovation.

A vibrant blend of recycled ETPU and EVA (where the accent colors come in), FLEKSsheet is sustainability in full spectrum. These sheets, made with up to 93% recycled foam, are ground, remixed, and precision-cut for versatile use—all while keeping tons of waste out of landfills and incinerators.

Our Impact.

Big Dreams, Big Impact

We measure the recycled content in each of our products by volume, the most honest expression of how much waste we rescue and repurpose in each shoe. Every pair, every product, is a small revolution in reducing our footprint—without ever sacrificing feel, function, or style.

Our Materials

Recycled & Repurposed, by Design

Our design process starts with what others discard: high-performance premium foams, beautiful character leathers, textiles made from recycled materials or deadstock that would otherwise end up in landfills.

Each material we repurpose has a story. A past life as factory overflow. A mis-cut. A scrap too small for mass production—but perfect for reinvention. We gather, grind, or reform these materials into something new, extending their lifecycle and redefining their purpose.

Our Process

We begin with what others leave behind

We're not perfect,

just better.

Our Mission

Fleks was born from the desire to revolutionize the footwear industry by providing the highest performance solutions fused with sustainable processes. We are dedicated to tackling environmental challenges caused by foam manufacturing and constantly working hard to create a greener, cleaner future.

Fleks Facts

- Our factory is Global Recycling Standard Certified, verifying our recycled products are processed in a more climate-friendly way

- Our midsoles use up to 85% recycled foam scraps from high performance athletic footwear manufacturers

- Fleks midsole production reduces greenhouse gasses by 65% compared to a traditional midsole

- Our process uses 99% less water (only 2 tablespoons!), and has no toxic wastewater runoff

- We use zero toxic chemicals in our production process. No PFAS, No PFC

- Why China? Our recycled foam is sourced close to our factory to reduce greenhouse emissions

- Our factory uses solar power

- Our packaging is made from 100% recycled materials and can be fully recycled or composted after use

- We ship with USPS because they’re already headed your way—fewer trips, fewer emissions, and a lighter footprint on the planet

For even more information about our sustainability efforts please click here

Here’s to Making Waves and building a more sustainable future, together.

Let’s Fleks.